Moisture content

It is not wrongly claimed that the moisture content is responsible for up to 90% of all problems related with the use of timber. Who doesn’t take care about these fundamental facts between timber and moisture content will make bad experience.

Strength property, processing, calorific value, utilization, quality of timber for pulp and the resistance of timber against fungus attack are based on moisture content of the timber.

In timber processing moisture content u (u) % is usually related to absolutely dry (absolutely dry = 0% moisture content) timber.

Moisture content of timber is important for:

- Weight of the log and processed timber

- Open air and kiln drying

- Degrading due to drying process failures

- Wood processing

- Deviations in moisture content and related dimensions changes

- Hazards due to fungal attack

Conifers just felled contain ~55-70% moisture content in average based on absolutely dry condition. Log center contains ~35-50% whilst the sapwood could contain ~100-150% moisture.

By comparison, hardwood just felled contains between 70% and 100% moisture content based on absolutely dry condition but poplar can contain up to 200% moisture content.

Just felled trees resp. logs are indicated green logs. The moisture content is similar to the living tree.

Moisture content (u %) is the value of water content in the timber.

Formula for the calculation of moisture content in practice: moisture content = (weight in wet resp. „green“ condition – absolutely dry mass) ÷ absolutely dry mass x 100 or as per the following formula

u (%) = (mu − mo) ÷ mo x 100

mu = weight in wet condition [g], mo = absolutely dry weight [g].

This calculation is required for exact determination of absolutely dry process (absolutely dry – 0% (r0) moisture content).

Relationship between moisture content and climate

Moisture content of timber changes if the climate condition changes too (temperature and relative humidity). Under humid climate conditions dry timber absorbs moisture whilst it releases moisture under dry climate conditions. During both climate conditions the timber reaches it equilibrium moisture content (EMC) = ugl [%].

The climatic dependency of moisture content is very important for the usage of timber as a change of moisture content below the range of fiber saturation uf *) raises to swelling and shrinkages of the timber. This fact is important for the usage of timber and must be covered during construction and design of buildings to avoid damages.

*) Fiber saturation uf is the point between free water in the cells resp. pores and bounded water content in the cell walls. This sector is within the range of ~26% moisture content.

Practically the equilibrium moisture content will never be reached finally because of the constantly changing climate conditions during the year. In addition, it must be considered that the climate conditions are different in the various zones of the earth.

In central Europe – at moderate climate conditions – the equilibrium moisture content ugl [%] during the year is within the range of 17%. At open air drying of timber in moderate climate zones the moisture could never dry down below ~16-17%.

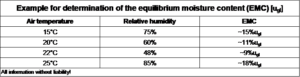

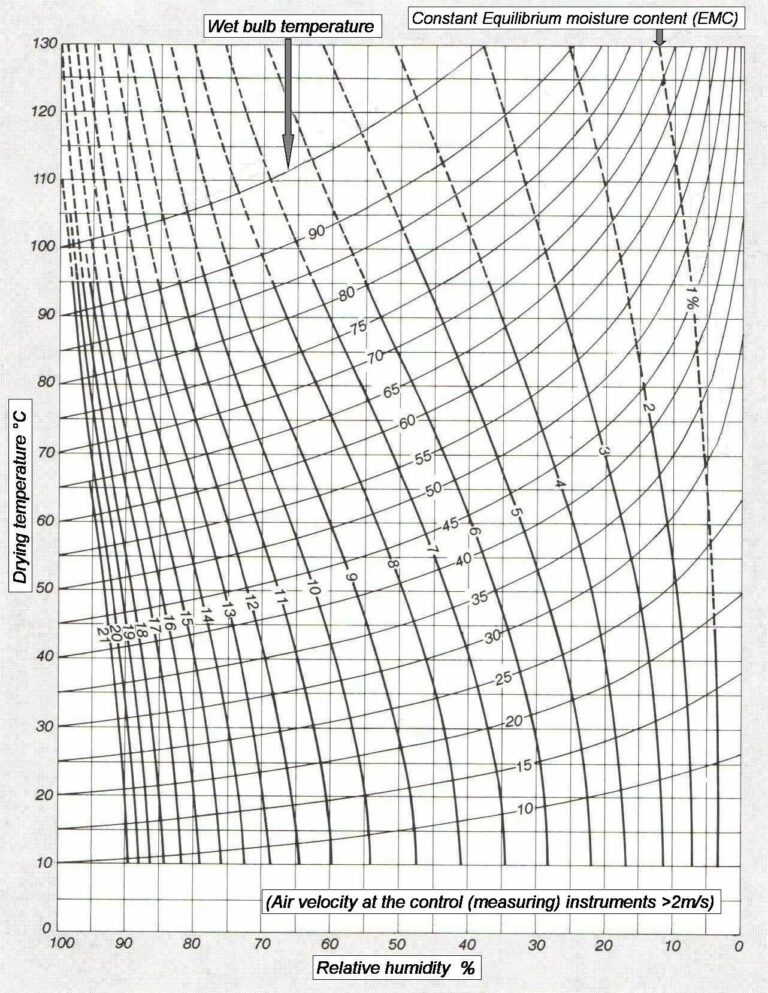

The following diagram – equilibrium moisture content – shows moisture content figures in relation to various climate conditions (temperature and humidity of the air). This table is for the calculation of swelling and shrinking factor of timber and is important for kiln process too.

*)

Sources:

Equilibrium moisture content (R. KEYLWERTH – USFPL 1951 – Picea sitchensis)

Example: At drying temperature of 45°C and relative humidity of 55% or wet bulb temperature of 36°C the EMC is 9%

Technologie des Holzes und der Holzwerkstoffe (Kollmann)

Springer Handbook of Wood Science and Technology ISBN: 978-3-030-81314-7 Peter Niemz, Alfred Teischinger, Dick Sandberg

Principles of Wood Science and Technology ISBN: 978-3 6428 7933-3 Franz F.P. Kollmann

Storch Industrie-Anlagen GmbH

Eilenau 123

GER 22089 Hamburg / Germany