Determination of Moisture Content

The drying method is used to precisely determine the wood moisture content (u%) by evaporating the water contained in the wood and is the most accurate and reliable method for determining the values.

The drying method – determination of moisture – must be carried out as follows: The wood to be tested (sample) is immediately weighed on a precision scale after it has been cut out of the board. The weighing result is the wet weight mu of the wood. The wood is then dried in a kiln (dry oven) at a temperature of 103°C ±2°C until all the wood moisture has evaporated. The drying time depends on the size and type of wood of the test specimen and takes several hours depending on the size and type of wood. The final weighing of the test specimen gives the dry weight mo. In order to be sure that the dry weight has been reached, it makes sense to weigh the test specimen several times (approx. 4-hour cycle) during drying. The dry weight mu (0% [r0] absolutely dry) is only reached after no more weight loss is registered.

In case of moisture measurements on sawdust or wooden chips, the procedure must be analogous (without cutting).

The moisture content u% is calculated according to the following formula:

u (%) = (mu – mo) ÷ mo x 100

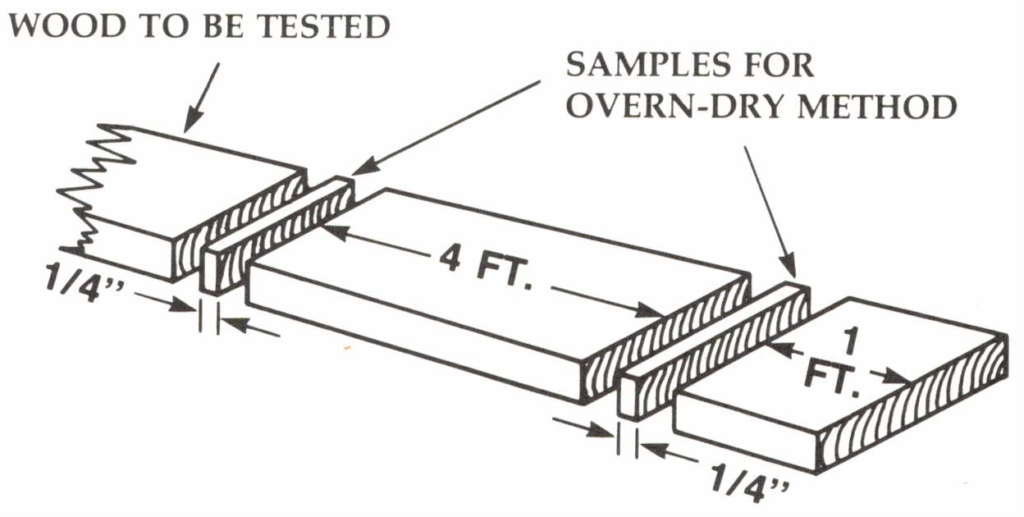

In order to obtain exact values from the kiln test, the following points must be observed: since the moisture within a board can vary greatly, the sample must be cut out as shown in the picture.

Suggested location of samples for oven-dry method of determination of moisture content.

(Conversion: 1 ft. = ~30cm / 1/4” = ~6.4cm / 4ft. = ~122cm)

Source: J.L.Bachrich – Dry Kiln Hand-Book (1980)

Distance from the front end of the board to the specimen area 1 ft. = ~30cm. The reason for this is that the board is generally drier in the front area than in the middle of the board. Particular care must be taken to ensure that the cutting process does not heat up the cut surfaces, otherwise moisture loss can already occur in the sample. Before weighing, all sawdust or chips must be removed from the sample. Immediate weighing and the subsequent drying process ensure that the dry weight is determined successfully.

Remark: In an emergency case, during unforeseen interruptions, aluminum foil will help, in which the sample is briefly wrapped airtight to prevent any moisture absorption.

For shortening the drying time, the sample can also be cut into smaller pieces with a chisel and all pieces dried and weighed together.

Attention: Caution: Any loss of specimen in the form of sawdust or chips must be avoided throughout the process, otherwise the result will be unusable.

Experience has shown that before the last weighing process on the precision balance, it makes sense to cool down the sample in the drying oven by switching off the heating.

In the laboratory of a woodworking company, a suitable kiln (dry oven) and an electronic precision scale are required for the dry test. The measurement result is recorded accordingly for quality verification.

Measurement of the wood moisture by electrical resistance method

The electrical resistance measurement will not be dealt at this point. For various reasons, this kind of moisture measurement cannot be dispensed within practice. There are measuring systems that work continuously and with which a continuous measurement can be carried out during the ongoing process.

Modern measuring systems for moisture measurement work without contact.

Springer Handbook of Wood Science and Technology ISBN: 978-3-030-81314-7 Peter Niemz, Alfred Teischinger, Dick Sandberg

Principles of Wood Science and Technology ISBN: 978-3 6428 7933-3 Franz F.P. Kollmann

Storch Industrie-Anlagen GmbH

Eilenau 123

GER 22089 Hamburg / Germany