Swell and shrink in relation to the direction of annual rings

During drying of timber in a kiln the humidity will be continuously reduced by simultaneous delivery of heat and air circulation. The drying process depends on timber species, dimensions and selected drying program (temperature / air humidity / air speed and drying gradient). The complexity of drying timber is not discussed here.

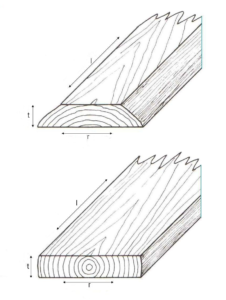

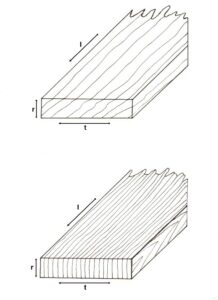

Plain resp. quarter sawn timber influence swelling and shrinkage.

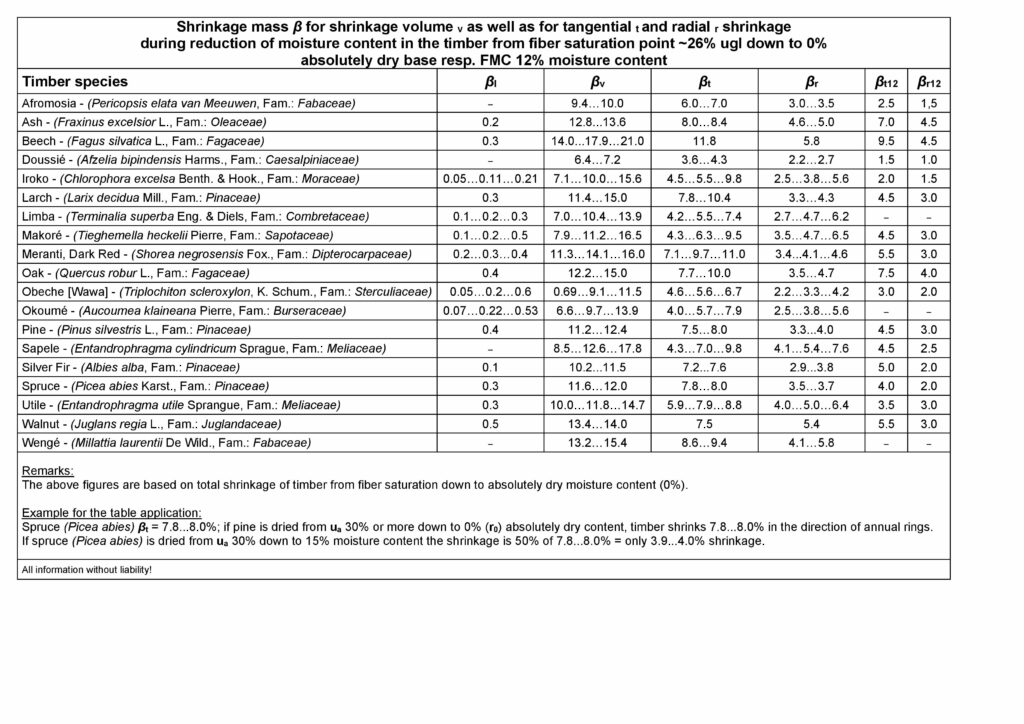

Shrinkage of timber in direction of fiber is 0.1%…0.3%…1% from green to absolutely dry content is small besides anomalies due to the growth of the timber.

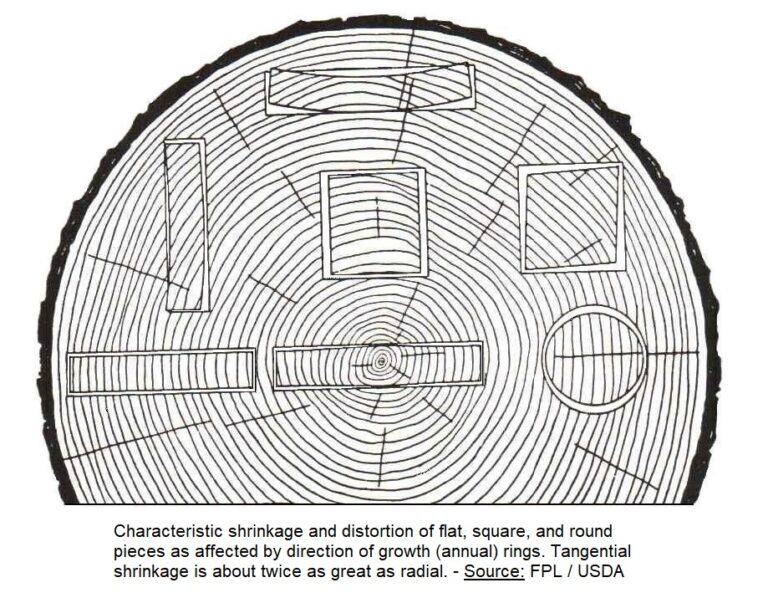

In radial direction of the annual rings the shrinkage is ~3%…5% whilst in tangential direction the value is ~5%…12%.

For this reason, wood warps more or less depending on the position of the annual rings.

Below the fiber saturation point uf 1) timber releases moisture and shrinks, vice versa timber swells if it absorbs moisture below the fiber saturation point uf 1). Both processes change the timber volume that means timber is alive.

1) Depending on timber species the fiber saturation point uf is at ~26% based on absolutely dry content.

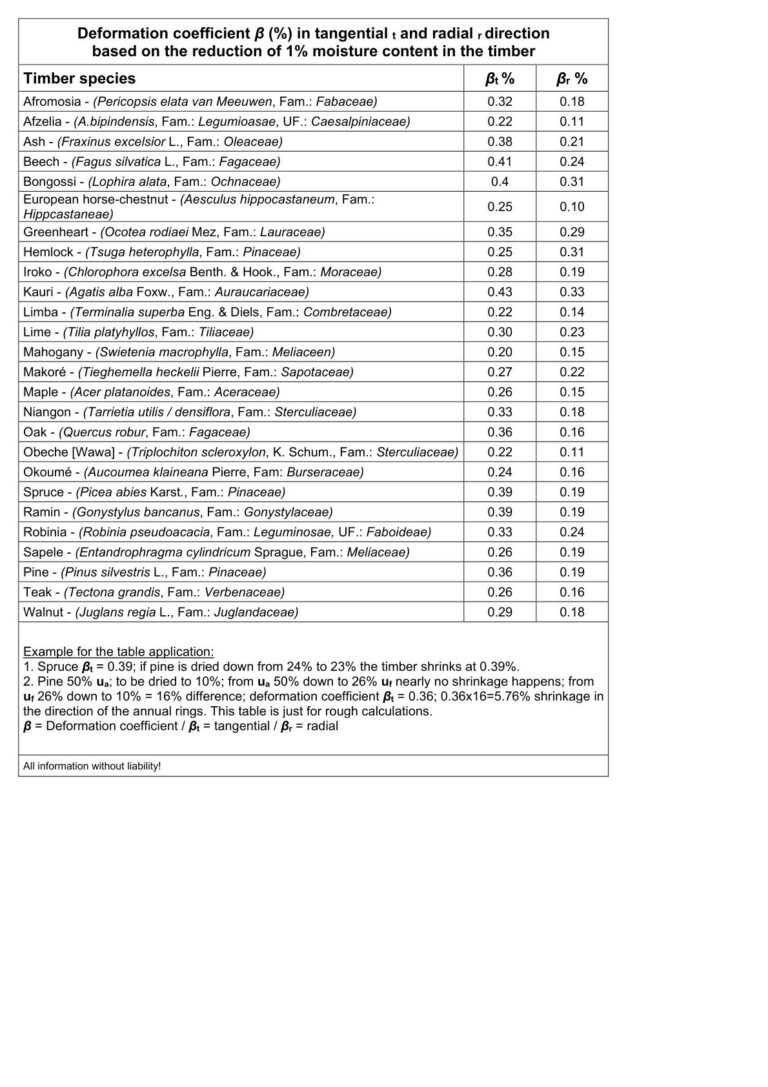

The volume of shrinkage and swell increases proportionally with the adsorption resp. resorption of moisture and will be additionally influence the density of the timber.

In case fresh sawn timber is dried down to ~26% moisture content only the cells resp. the pores release moisture without essential shrinkage but not the cell walls. Shrinkage increases proportional with the loss of bounded water (moisture) from the cell walls. Shrinkage and swelling are mainly limited to the part between the fiber saturation point and absolutely dry content = 0% (r0).

Swell and shrink in relation to the direction of annual rings:

direction of fiber = l – annual ring direction radial = r

annual ring direction tangential = t

The reduction of damages due to shrinkage and swelling is a part that must be resolved during the production of timber by means of the design and construction.

The max. width of board is limited due to the log dia. and cutting pattern. Only lamination of boards makes it possible to get wider boards resp. panels. In the solid wood panel production mainly, small lamellae are laminated laterally-reversed to get wide dimensioned panels. The reason is to reduce resp. control shrinkage and swelling. Additionally, the direction of the annual rings is most important und must be taken under serious consideration.

Another possibility is the lamination of various layers (3-layers, 5-layers etc.) of timber (veneer, lamellae, boards etc.) for the reduction resp. control of shrinkage and swelling. Plywood and parquet besides many other engineered products are typical examples for this kind of “work” (swell / shrink).

For the optimization of the final product a close cooperation with the sawmill resp. supplier of the timber is strongly recommended.

Storch Industrie-Anlagen GmbH

Eilenau 123

GER 22089 Hamburg / Germany